The Factory Acceptance Test (FAT) is a process that evaluates the gear during and after the meeting process by verifying that it’s constructed and operating in accordance with design specs. FAT ensures that the components and controls are working correctly in accordance with the functionality of the tools itself. As the name suggests, this testing is carried out on the manufacturing unit.FAT is typically performed so as to assess any discrepancies and non-conformities, in addition to develop a course of for a way they’re to be dealt with. A poor or rushed FAT can result in missed non conformities, which might solely then be corrected after the equipment is installed—which in turn can wreak havoc on a project schedule. FATs are helpful not only for the client and end customers however for the producer as nicely. Both events could be factory acceptance testing assured that the tools meets all the contractual specs and any issues can be addressed before arriving at the customer’s site.

- A repair you would have accomplished in a single day may end in an costly fix that takes weeks down the street.

- Work together with your provider, and your supplier will work with you.

- This allows the end consumer to work with a single firm and additional differentiates ACS from a typical machine builder or techniques integrator.

- You can repeat the same process for all the different inputs as properly.

- Prior to the shipment of the system to the shopper, the seller normally performs tests to ensure the system meets the customer requirements.

Electrical Set Up Inspection Fulfilling Trakhees Pointers To Acquire Operation Health Certificate (ofc)

The product have to be assembled, ready, and connected to utilities for testing. Documentation similar to drawings, ASME certificates, and take a look at procedures have to be gathered. And lastly, testing have to be conducted within the manufacturing facility that follows particular test procedures.Before the FAT begins, the producer ought to current the FAT process to the shopper https://www.globalcloudteam.com/ for evaluate and approval. The procedure should embody testing of as much performance as is sensible within the factory and, the place possible, should present pass/fail standards or desired outcomes for each item tested. Once the process is accredited, the producer should test the equipment before the FAT begins. Keep in thoughts that some clients like to go to the manufacturing facility throughout FAT, so this “pre-test” will affirm that the sterilizer is ready up with the correct choices, guarantee a smoother FAT process and minimize down-time during the FAT.

What Are The Method In Manufacturing Unit Acceptance Testing?

Testing period will depend on what type of plant and equipment is being reviewed. Not all Plant and Equipment on a project will must be manufacturing unit tested. It will depend upon the necessities set out in the Owners Project Requirements [OPR] and Commissioning Plan/Specification. Do you have expertise and expertise with the matters talked about in this content?

Guarantee Confirmed Quality And Compliance Of Your Bought Equipment With Our Manufacturing Unit Acceptance Checks

Here’s the factor with new systems, particularly give the extent of complexity you’ll discover with CPI tools – it’s not unusual for there to be minor glitches the primary time they are powered up. The good thing about conducting an FAT is that the manufacturer can deal with typical first-run issues, sometimes even prior to the shopper arriving. The following is a list of supplementary checks which could be carried out on MTU Onsite Energy engine-generator sets. Most sellers leave no less than two weeks before the machine ships. Depending on the gear, you may carry out FAT for patrons in a day or a week if you need further fixes, extending the method further.

Would You Want A Free Manufacturing Facility Acceptance Test Checklist?

Our manufacturing unit acceptance testing services offer extensive options to make sure the quality and compliance with specs and contractual requirements for equipment and elements. Make certain that your equipment or plant performs as anticipated beneath a full vary of foreseeable situations and keep away from costly contractual penalties if you are a producer or project downtimes if you are an operator. Prior to the shipment of the system to the shopper, the seller normally performs checks to make sure the system meets the customer requirements. The complexity and completeness of those exams is very depending on the automation system to be supplied and the scope of provide offered by the seller.

Bringing Vision And Performance Together

It aims to identify any potential problems with the gear or system before it is installed so that these problems can be addressed earlier than the tools is put into service. Ensure that the equipment you ordered is in accordance with specifications prior to shipment. By defining the scope of the FAT, we be certain that the gear offered is suitable and credible. This plan is shared with the shopper from the start to ensure it aligns with their expectations and requirements. Where system design consists of main microwave network, there may be a separate FAT for the microwave subsystem at a unique location. It isn’t sensible to arrange precise RF microwave hyperlinks in factory settings.

Extra Manufacturing Facility Acceptance Testing

The consumer will eventually perform a site acceptance check (SAT) upon proper set up at the permanent operation place. The SAT further verifies tools efficiency in relation with different methods at the web site. The main benefits of FAT testing are that it provides peace of thoughts to the customer that the gear will meet their expectations and permits any issues to be identified and rectified before the equipment is delivered.

Demonstrate Gear Efficiency

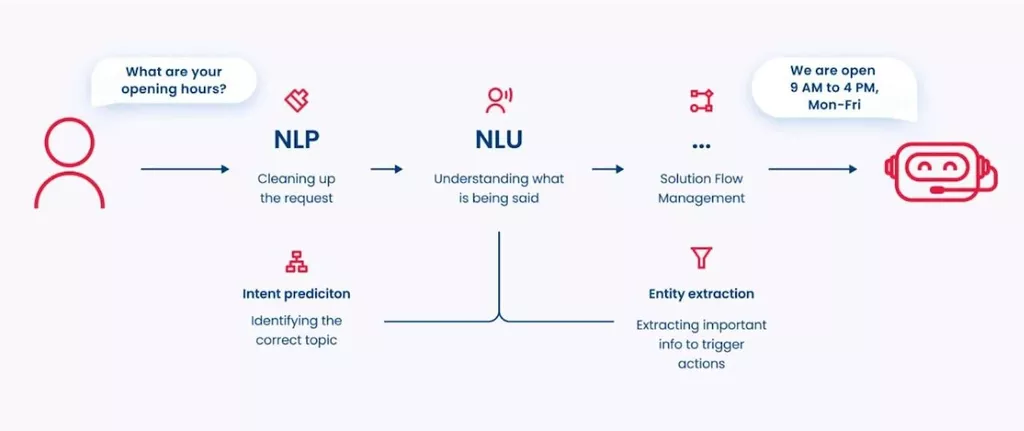

A Factory Acceptance Test (FAT) is a sequence of tests performed on equipment and techniques prior to set up on the customer’s site. It involves functional testing of the system, as properly as testing of the system’s hardware and software. These tests are carried out to confirm that the gear meets the required necessities and functions as intended. A Factory Acceptance Test (FAT) is a course of during which a manufacturer exams a machine or system before it is delivered to the client. The objective is to make sure that the machine or system meets the necessities that have been ordered by the client. A Factory Acceptance Test (FAT), is usually performed at the manufacturer’s facility and will include useful testing and performance testing.

Verify pressure, temperature and material information on the National Board nameplate to be according to specifications/P&ID and ensure presence of ASME “U” stamp. Witnessed extended-run tests should be scheduled and approved a minimal of 4 weeks previous to the engine-generator set’s scheduled ship date. Any requests for witnessed extended-run testing after this four-week period have to be accredited and are subject to additional fees.

It’s the one method to confirm that the equipment meets all settlement points. Therefore, either side are certain they observe the contractual specifications to the smallest detail. The Factory Acceptance Test (FAT) is a test of subsea tools earlier than set up, which is at all times carried out on newly manufactured tools, to examine whether or not the tools satisfy the performance and function requirements or not. Extended Factory Acceptance Test (EFAT) could also be solely applicable for a number of equipment or subsea buildings, e.g., subsea timber with sub-assemblies.

Water check – this procedure simulates the system in operation to offer proof of performance. These exams often embody verification of relevant documents, together with consumer manuals, P&IDs and any sort of instructions that come with the equipment to make sure they’re correct. The patrons and sellers ought to work collectively throughout the whole project.

It’s widespread follow to incorporate FAT price concerns within the preliminary project scope. Therefore, the client shouldn’t should pay further for a manufacturing facility acceptance check. On the other hand, the client must point out what tests they wish to run.